Altair® Flux® Applications

Flux is used widely across multiple industries such as transportation, electrical equipment, and consumer goods to develop more efficient electrical systems with higher levels of connectivity.

Flux addresses the broadest set of electromagnetic, electric, and thermal simulations, and is closely linked to Altair global solutions for multidisciplinary design exploration and optimization. It gives the power to inventors to help accelerate the electrification of their equipment while offering higher levels of performance, improving the time to market, developing cost-effective solutions, and delivering efficient and reliable designs.

Learn More About FluxRotating Machines Multiphysics Optimization

Whatever the industry, the design of high-performance e-Motors is a complex undertaking. Altair® FluxMotor®, Flux and Altair’s suite supply engineers a robust solution to examine conflicting constraints like efficiency, control, temperature, weight, size, and cost.

To explore more concepts quicker, better understand their designs and improve performance, Altair’s workflow guides motor designers through an efficient process of simulation-driven design. This analysis and optimization solution supports multi-disciplinary teamwork and reduces design time.

Smart Sensors Design

As most industries look at developing smarter connected equipment, using Flux to develop appropriate sensing technology enables accurate prediction of the detection range, measurement error, or condition of operation.

Actuators Optimization

Electromagnetic actuation is widely used for control and safety in numerous industries and wireless appliances. Flux can optimize the performance in terms of speed, torque or energy consumption, and integrated in a more global system for advanced control and positioning analysis.

How can we help you solve your electromagnetics problems?

Contact UsHigh- and Medium-voltage Powergrid Equipment Design

To deliver electricity more reliably, efficiently and with more flexibility, powergrid infrastructure has to be modernized. Failure of critical high-voltage equipment like power transformers, circuit breakers and insulators have a very high impact on cost.

Flux ensures robust electrical and thermal analyses to attain the highest levels of efficiency, reducing the losses and optimizing the global performance.

With global trend to operate such equipment closer to their performance limit, Altair’s solutions include structural constraints to evaluate fault risks in a comprehensive and accurate way.

Wireless Charging Analysis

With all wireless applications booming, there is a tremendous demand for convenient and high-speed contactless vehicle charging.

In the race to get innovations to market, Flux delivers a powerful solution by optimizing the energy transfer while considering a variety of constraints such as losses, system misalignment, radiated field, and interferences and thermal concerns.

Heat Treatment Process Optimization

Heat treatment is an industrial, thermal and metalworking processes used for a variety of purposes such as welding, hardening, or sealing.

From power source configuration through optimal inductor shape and forced cooling options predicton, Flux simulates the complete process to optimize the heating and forced cooling phases. Engineer obtain the most efficient heat treatment without adversely affecting the parts, but also to reduce energy costs incurred from the repetitive high current consumption.

Featured Resources

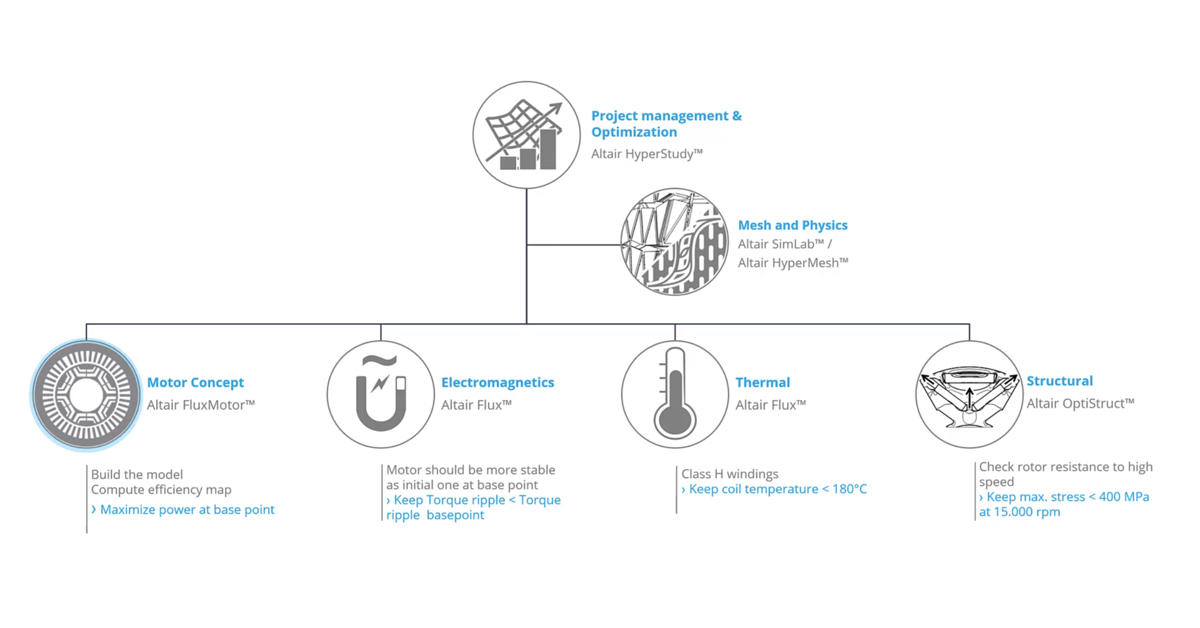

Electric Motors Multidisciplinary Optimization Platform

The design of a high-performance e-Motor is a complex undertaking. Engineers have conflicting constraints to consider including efficiency, temperature, weight, size and cost. To explore more ideas, better understand their designs and improve performance, Altair HyperWorks™ has a workflow to guide motor designers through an efficient process of Simulation-Driven Design. This analysis and optimization solution supports multi-disciplinary teamwork and reduces design times.

E-motor Design using Multiphysics Optimization

Today, an e-motor cannot be developed just by looking at the motor as an isolated unit; tight requirements concerning the integration into both the complete electric or hybrid drivetrain system and perceived quality must be met. Multi-disciplinary and multiphysics optimization methodologies make it possible to design an e-motor for multiple, completely different design requirements simultaneously, thus avoiding a serial development strategy, where a larger number of design iterations are necessary to fulfill all requirements and unfavorable design compromises need to be accepted.

The project described in this paper is focused on multiphysics design of an e-motor for Porsche AG. Altair’s simulation-driven approach supports the development of e-motors using a series of optimization intensive phases building on each other. This technical paper offers insights on how the advanced drivetrain development team at Porsche AG, together with Altair, has approached the challenge of improving the total design balance in e-motor development.

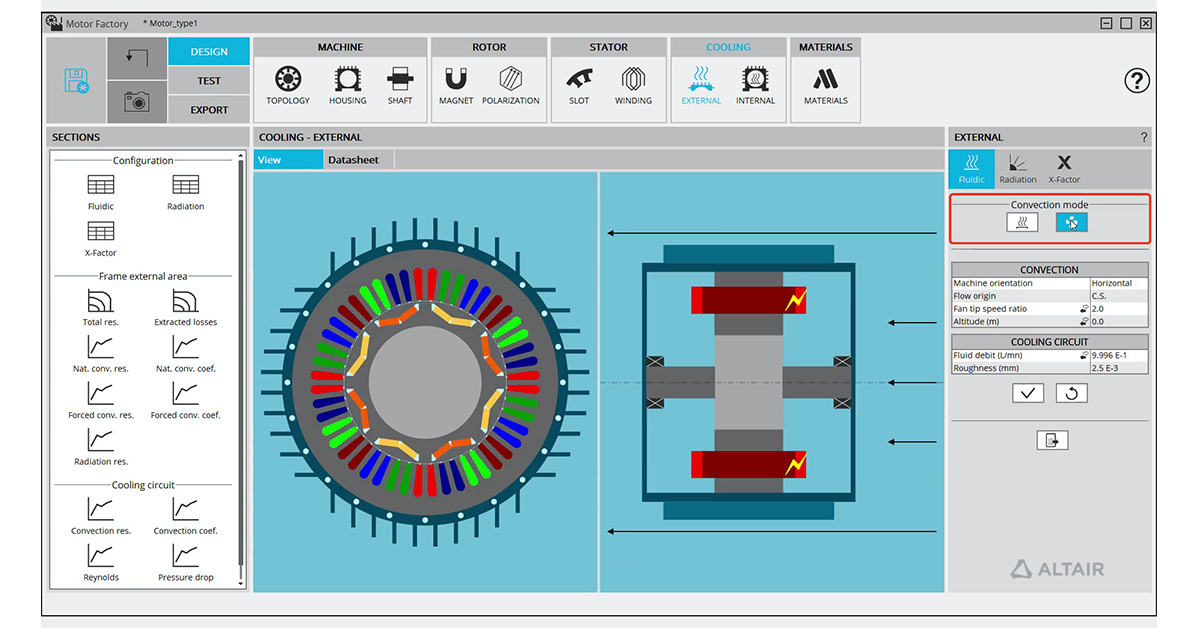

Altair FluxMotor - Thermal Design, Test, and NVH Evaluation

The latest release of FluxMotor, Altair's software product for electric machines design, adds several functionalities in the area of thermal design, test, and NVH evaluation. This short video illustrates some of the major updates.

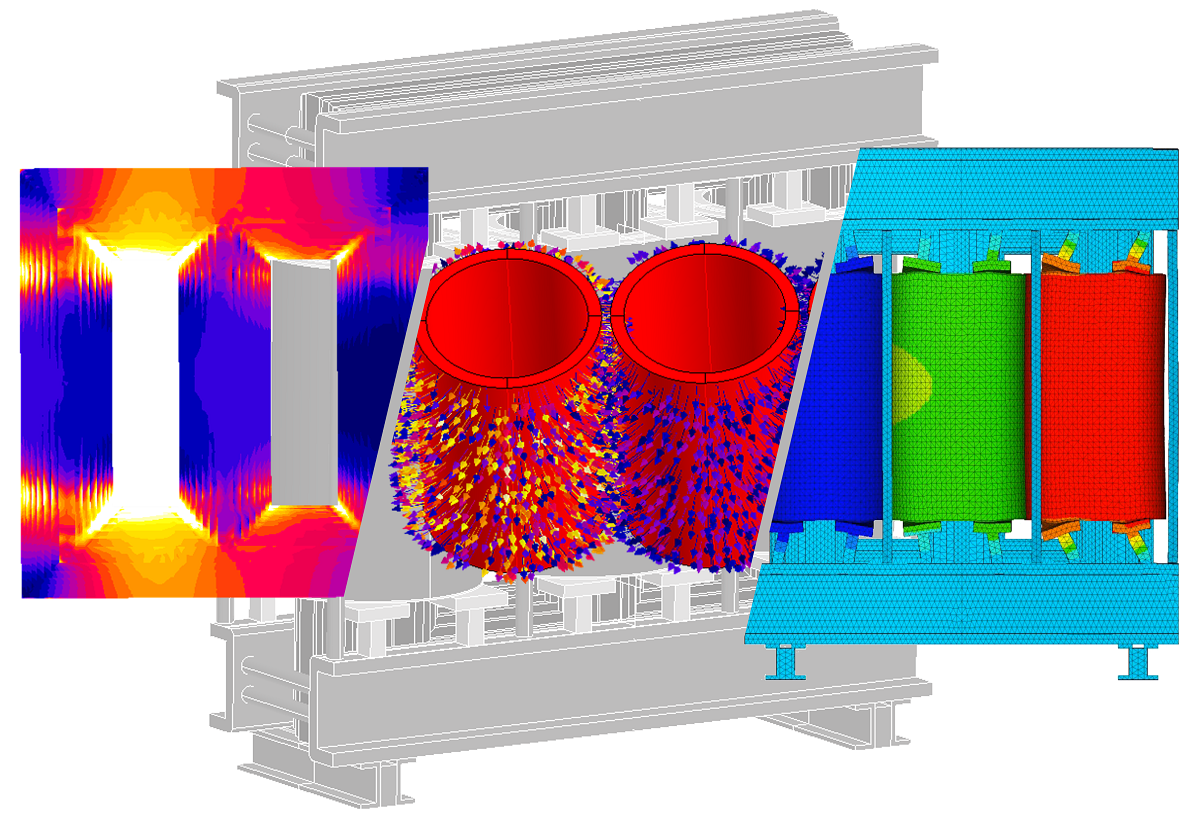

Power Transformer under Short-circuit Fault Conditions: Multiphysics Approach to Evaluate the Robustness

Transformers’ windings experience mechanical loads from electromagnetic forces due to the currents they carry. Power transformers can suffer from high sudden short-circuit currents. These short-circuit currents are a significant threat, not only from an electrical but also from the structural integrity point of view. In this paper, coupled electromagnetic and structural mechanics simulations are carried out to evaluate short-circuit fault risks in a comprehensive and accurate way.